large capacity peanutsunflower screw oil expeller in nigeria

- Usage: edible Peanut germ oil refining unit

- Type: edible Peanut germ oil refining unit

- Production Capacity: 100 kg/h - 1000kg/h

- Voltage: 220V/380V/440V

- Power(W): 5.5-22KW

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Raw material: Peanut Seed

- Name: Edible Peanut germ oil refining unit

- Material: Stainless Steel SS304/316

- Application: Oil Production Line

- Function: Chemical oil refining and physical oil refining

- Application range: 10-1000tpd

- Advantage: Low consumption

- Power consumption: 17.5kwh-24kwh

- Steam consumption: 200-300kg per one ton crude oil

Oil Expeller, Vegetable Oil Extraction Plant - Goyum Screw Press

We are a leading manufacturer and exporter of Complete Mechanical Oil Extraction Plant, Solvent Extraction Plant, Cooking Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Palm Kernel & other Oil Expeller Spare Parts and EFB, MSW, Plastic & Industrial Shredder. Exported to 60+ Countries.

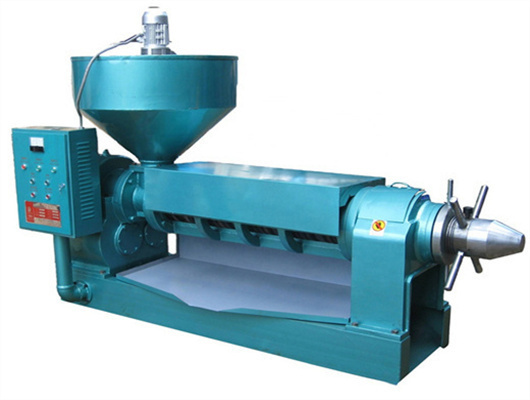

Sunflower screw oil press machine is a larger capacity screw oil press machine than 0.5-2MT/24hr oil expeller. It makes use of screw-driving force to squeeze oil from plant seeds like rapeseed, canola, mustard, sunflowerseeds, soybeans etc. This model sunflower screw oil press machinery is of simple structure, it is easy toinstall, operate and

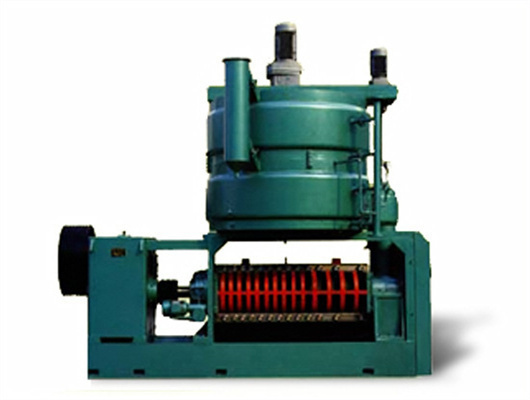

Large Capacity Oil Processing Machine

This Expeller has Two Chambers made of Cast Steel. Feed Side: Ø 16″ x 50″ Long, Discharge Side : Ø 16″ x 50″ Long. Hard Faced Worm Assembly, Discharge Ring. Main Worm Shaft can be withdrawn without disturbing the Gear Box. Chamber Lifting system is motorised. Kettle : 8 Stages with Steam Jackets of Ø 78”for efficient cooking of Seed.

These oil extraction machines gather vegetable oil from oil-bearing seeds and nuts for food and industrial uses, including biodiesel and other fuels. Our durable, heavy-duty oilseed equipment has an average life span of 60-70 years, operating with maximum productivity and lower processing cost per ton. Download our literature on screw presses

Design and Construction of a Palm Kernel Oil Extraction.pdf

Several factors are known to affect mechanical oil expression from oilseeds. In this study, the influence of kernel moisture content (KMC), kernel heating temperature (KHT), kernel heating duration (KHD) and kernel particle size (KPS) on palm kernel oil (PKO) yield by a mixed variety of oil-palm kernels using a locally fabricated screw press was investigated.

This is a large scale palm kernel oil processing project set up in Nigeria. The production capacity is 120 tons per day. It is a complete plant including Seed Cleaner, GOYUM 27 – Screw Oil Press, Material Handling Equipment, Screening Tank, Oil Filter Press Machines and Control Panel. Below are a few glimpses of the PKO Plant.

Design, Development and Performance Evaluation of an Improved Palm

Khan and Hanna (1983) designed a screw press that ruptures oil cells under pressure, expelling oil through slots between cage lining bores. The capacity of a screw press depends on the size of the cage holding the product (UNIFEM, 1987). Small power-driven expellers requiring about 8 hp can

Plate 1: Side View of the Oil Palm Screw Press (Adetola et al., 2012) Results of performance test showed that the highest oil extraction ratio (OER) of 17.90% and oil extraction efficiency (OEE