soybean argan oil expeller in congo

- Usage: Soybean oil mill machinery

- Type: Soybean oil mill machinery

- Production Capacity: according to the capacity

- Voltage: 220v,380v,440v

- Power(W): 5.5KW, 7.5KW, 15KW, 18.5KW

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: CE,BV,ISO

- name: Soybean oil mill machinery

- raw materials: fresh Soybean

- end product: virgin Soybean oil, Soybean meal

- texture: stainless steel,carbon steel

- package: wooden case special for cold pressed Soybean oil machine

- other materials: Soybean Oil ,Soybean, seLDe

- using main business: South East Asia,Middle America,West Africa

- using life: more than 15 years

What is Expeller Pressed Oil and Why Does it Matter?

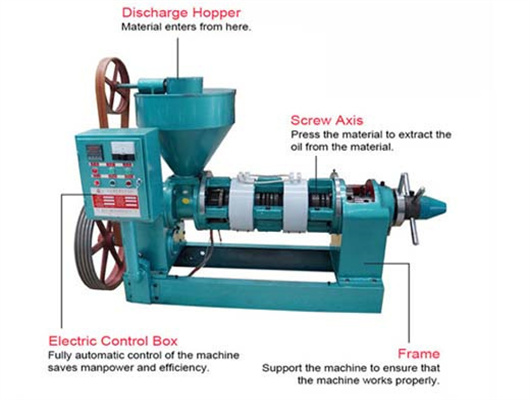

Applying heavy pressure to olives or seeds until oil starts seeping out. An expeller is a big screw that is tightened until it crushes the nut/seed and causes the oil to run. This method provides yields of only 65-70% of the oil. Many companies then try to extract the rest of the oil using the chemical solvent.

energy content because of the residual oil in the finished product. E/E Soybean Meal will have a darker color and a desirable roasted nut aroma; in addition, the product will be slightly coarser in texture with less dust than conventional, solvent extracted soybean meal. Storage and Handling E/E Soybean Meal is available in bulk, and as such stored

Turnkey Soybean Oil Processing Project Installed In Africa

This is a turnkey soybean oil mill plant established in Africa for one of our customer, and this unit consists mainly of oil expeller, oil filtering equipment, cooking kettle, cleaning equipment, etc. It is a turnkey project with a raw material extraction capacity of 50 tonnes per day. If you are interested in starting your own soya bean oil

Expeller pressing gets 87-95% of the oil out of the seed, so there is some oil still left over after pressing (though some claim as little as 65% is removed, so this is debated). Therefore, this option is not the cheapest, which can make this oil more expensive than the solvent expelled standard. Expeller pressed oil is typically refined (or

What is the Difference Between Cold Pressed, Expeller Pressed

Expeller pressing gets 87-95% of the oil out of the seed. This makes this option more expensive than the solvent expelled standard. Expeller pressed oil is refined using the same process described above. This refining process involves additional heat from steam and use of a natural earthen bleaching clay.

Heavy pressure is applied to olives or seeds and oil starts seeping out. An expeller is basically a big screw that is tightened over nuts/seeds/fruits until it crushes them and causes the oil to run. This method provides yields of only 65-70% of the oil, and thus many producers continue to extract the remaining oil using the chemical solvent.

Debunking The Debate Between Expeller Pressed Versus Cold

The Anderson Super Duo Expeller® utilizes two presses in a single pass to extract oil more efficiently, making it ideal for cold pressing. But just because there’s no external heat added in cold pressing doesn’t necessarily mean there’s no heat involved. Heat often sneaks into the process early on, to dry the raw oilseed material for

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

- Can two-stage extruding-expelling process improve soybean oil yield?

- To examine the viability of this improved two-stage extruding-expelling process, techno-economic analysis was performed by using SuperPro Designer for simulation of the soybean extruding-expelling process. Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%.

- What is expeller pressed soybean meal?

- Feeding the world responsibly with Expeller-pressed, sustainably-produced, chemical-free, soybean meal. As soybean production increased in Kentucky over the last few decades, some producers were transporting their harvest hundreds of miles to reach feed mills and soybean crush plants to process their crops.

- How profitable is soybean oil & soybean meal?

- Soybean oil yield increases to over 70% compared to the conventional single-step expelling process with 60%. Soybean oil and soybean meal contributed about 25% and 75% of total revenues, respectively. Through fluctuations in economic conditions, soybean meal plays an important role in earning profits, making the whole mechanical process profitable.