expeller pressed sunflower oil production in ghana

- Usage: For Sunflower oil extractors usage

- Type: For Sunflower oil extractors usage

- Production Capacity: 50-1000 t/d depend on your requst

- Model Number: JXSE760

- Voltage: 380V

- Power(W): As Sunflower oil extractors capacity

- Dimension(L*W*H): As Sunflower oil extractors request

- Weight: As Sunflower oil extractors output

- Item: Sunflower oil extractors

- material: stainless steel

- residual oil in cake: less than 1%

- raw material range: Sunflower Oil ,plam kernel ,Sunflower ,

- extractor system: Toasting system

- Moisture in meal: 12~13%

- Residual solvent: 300ppm

- Solvent: NO.6 solvent oil

- Solvent consumption: 4kg/t

- Mechanical impurities: 0.2%

Ghana to start cultivating sunflower in large quantities in 2024

The Tropical Agricultural Marketing and Consultancy Services (TRAGRIMACS) on Wednesday launched a Ghana Sunflower Project for the cultivation of sunflower in large quantities in the country from 2024.

Expeller pressing is the mechanical method for extracting oil from seeds and nuts. It involves crushing the raw material, such as soybeans, sunflower seeds, or olives using a mechanical press without the use of chemicals or excessive heat. Cold-pressed oils are extracted using a similar mechanical process as expeller pressing, but the raw

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier.

Among modern techniques of essential oil extraction are chemical distillation, cold pressing, and expeller pressing. When looking through aisles of essential oils, it might be confusing to decide which extraction method suits your needs. This article will guide you through the evolution of essential oil extraction methods and the difference between cold pressed and expeller pressed essential

Modern sunflower oil production: beyond smashing seeds

The sunflower oil production elevator pitch: Modern practices make sunflower oil production highly sustainable, even in harsher climates. Sunflower oil has a huge variety of uses: culinary, cosmetics, and much more. High-oleic sunflower oil is more stable, making it superior for skin care (plus it’s trans-fat-free) Cold-pressed means more

Expeller pressing (also called oil pressing) is a mechanical method for extracting oil from raw materials. The raw materials are squeezed under high pressure in a single step. When used for the extraction of food oils, typical raw materials are nuts , seeds and algae , which are supplied to the press in a continuous feed.

Sunflower Oil : Everything we need to know - Goyum Screw Press

Here are the top 5 countries in domestic consumption of sunflower oil in 2022: EU-27 (5,070,000 metric tons) India (2,550,000 metric tons) China (2,197,000 metric tons) Russia (2,100,000 metric tons) Turkey (1,190,000 metric tons) These countries consume a

By Guru July 27, 2023. Expeller pressing is a mechanical method for extracting oil from raw materials, such as seeds, nuts and algae. It is one of the most widely used methods in the oil industry, as it can produce high-quality oils with high efficiency and low cost. In this article, we will explain the expeller pressing technique, its

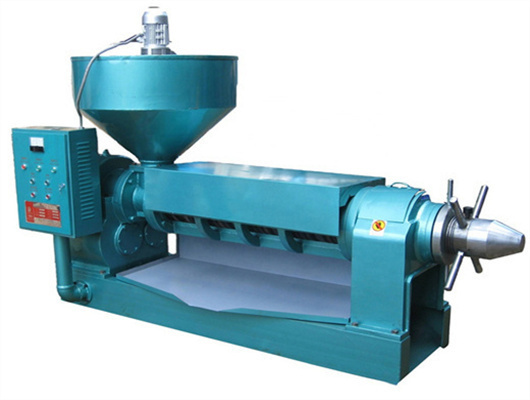

- What is a sunflower oil press machine?

- This is a mechanical method (An oil press machine) used for extracting oil, suitable for both large-scale and small-scale production of sunflower oil. It can be used for the initial processing of sunflower seeds to extract oil and leave behind oil cake. Sunflower oil can be pressed using either cold-pressed or hot-pressed methods.

- Is expeller-pressed sunflower oil better than solvent extraction?

- While the solvent extraction method has a lower residual oil rate, it might entail a significant solvent consumption, resulting in elevated production costs for sunflower oil processing plants. Consequently, many oil production plants are inclined to opt for the method of expeller-pressed sunflower oil, achieving the desired production outcomes.

- Why is expeller pressed sunflower oil a good investment?

- The method of expeller-pressed sunflower seed oil is popular with investors due to its relatively lower investment costs and the adaptable scale of oil production it offers. This approach allows for the construction of both full-scale sunflower oil plant and small sunflower oil mills, making it more accessible to most investors.

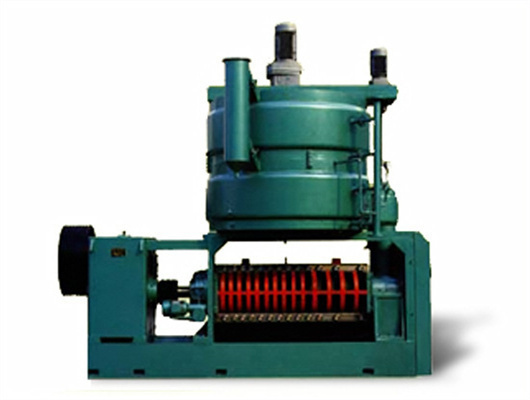

- What is a solvent extraction machine for sunflower oil?

- Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It’s worth noting that solvent extraction machine is costlier.