Soybean Oil Production Line

- The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.

- Service: Customization, installation, guidance, and training

- Cooperation: Factory Directly

- If you are interested in Soybean Oil Production Line, please leave us a message.

The physical pressing line requires raw materials to be carefully selected, and the soya bean is pre-treated through cleaning, crushing, softening, rolling and extruding. After that, the cleaned beans are added during the pressing process and the oil is extracted from the pressing machine, and the finished oil is produced by using high-tech physical refining filtration purification technology. The physical pressing method maintains the original flavor of soybeans, rich in vitamin E, and has a long shelf life. And the screw pressed oil has no additives, no solvent residue, and no soap content. Soybean oil pressing line is a combination of modern and traditional technology that produces pure natural soybean oil.

Main Sections of Completed Soybean Oil Production Line

1.Pre-treatment section

Before the oil is prepared, the pretreatment of soybeans requires cleaning, crushing, softening, rolling, extruding, etc. for the soybean oil processing industry.

1.1 Soybean Cleaning

Soybean should be cleaned first. The main purpose of this section is to remove the impurities of soybeans. The impurities are mainly plant impurities (such as bean stems, pods, etc.), metal impurities and non-metallic impurities.

1.1.1 Main equipment

Magnetic separator: adopts magnetic force to remove metal impurities by using the magnetic difference of various ores or materials, the metal impurities are usually nails, small iron wire, etc. Removal of metal impurities avoids the abrasion on the machine in the subsequent work.

Vibrating cleaning screen: The raw material may contain soil, leaves, stems and other ball impurities, which need to be cleaned up before the subsequent process. High-frequency vibration equipment can effectively remove impurities by using differences between oil and impurities in particle size, with the help of the relative movement between impure oilseed and sieve surface, finally, the impurities larger than or less than oilseed can be removed through the sieve hole. This kind of cleaning sieve is suitable for medium and large factories.

1.2 Soybean Crushing

After cleaning, the soybeans are sent to the crushing section, the main purpose is to crush the soybeans and separate the soybean skins from the bean kernels.

1.3 Soybean Softening

Softening is through the adjustment of oilseed moisture and temperature to improve the elasticity of seed so that it has the best conditions for rolling. Softening is mainly used for seeds with low oil content, low water content, poor physical properties and hard texture. Soybeans have low oil content and poor plasticity, which need to be softened before rolling. Softening temperature should be based on the level of soybean moisture. When soybean moisture is 13%~15%, the softening temperature is usually controlled at 70~80℃, and the softening time is 15~30 minutes. The commonly used softener for soybeans is a horizontal softening pot, which has a better softening effect.

1.4 Soybean Rolling

Soybean rolling is the process of using the mechanical function to roll the oilseed from the granular to flake.

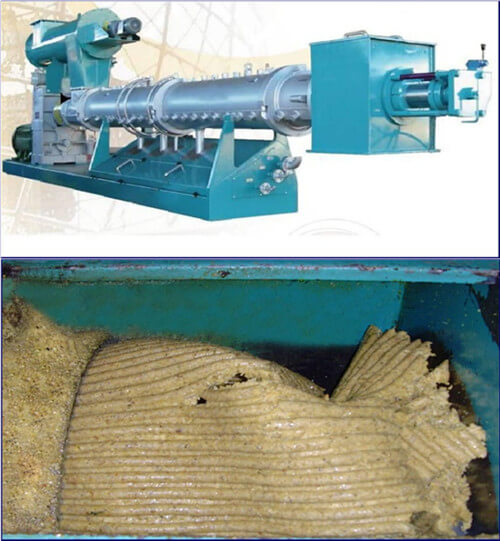

1.5 Soybean Extruding

Soybean extruding is the process of using extrusion equipment to break through the crushed, rolled soybean into porous, expanded granular material. Extrusion is a kind of high temperature and short time processing. At present, the commonly used soybean extruding machine is low moisture single-screw extruder, and the material is extruded by heating, pressing, gluing and vacuum extrusion. Generally, extrusion temperature can reach 110~200℃, and the residence time in the extruder is for the l~3 minutes.

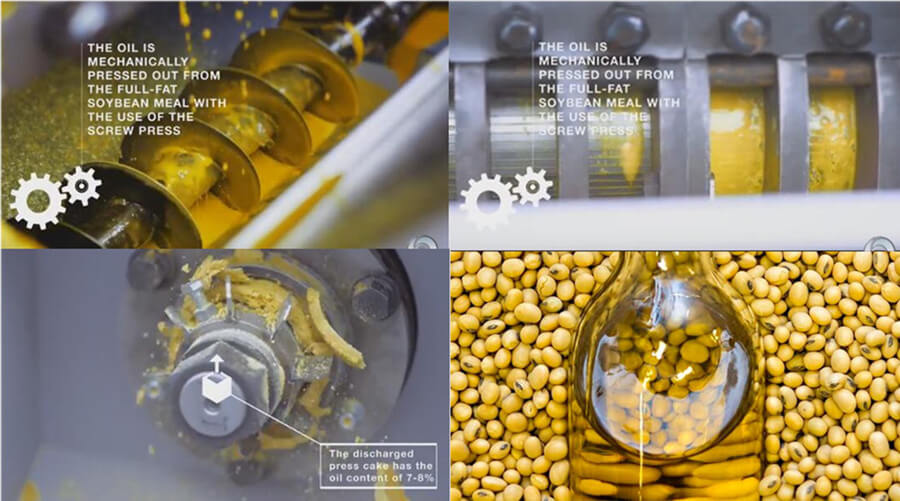

2.Oil pressing section

Oil pressing is a mechanical extracting method by using screw press to squeeze oil out from clean materials under pressure. The capacity of oil screw press is from 1 to 50 tons per day, which are commonly used for continuous mechanical extraction of oil these days, regardless of the size of the operation. There are many factors that affect the efficiency of oil extraction, such as vegetable seed types, temperature, press configuration, etc. Usually, the physical pressing method has an oil output of 65-70%, which is suitable for commercial processors to build small and medium screw pressing oil plant.

Cold Pressing

Today, the soybean oil is divided into cold pressed oil and hot pressed oil. The cold-pressed soybean oil has a lighter color and a lighter raw smoky taste. The hot-pressed soybean oil has high oil yield due to the high-temperature treatment of the raw materials, but it has a darker color and a stronger green bean odor. Therefore, the commonly used oil screw pressing method is cold pressing: the physical pressing method has irreplaceable technological advancement for the pursuit of green, authentic, healthy food. In order to achieve additional oil recovery, the seed material must be subjected to a longer retention time of high pressure in the screw press. Higher pressure is mainly achieved by lower seed moisture, resulting in high friction in the press. Because of the mechanical strength, the maximum diameter of the press cage is determined. The higher the pressure, the more limited the capacity of the press is. Moreover, the longer the retention time is required, the lower the shaft speed is required. This further limits the capacity. Therefore, the cold press is characterized by a capacity of only 1/10 of the capacity of the modern pre-pressing machine. But cold press machine can screw out 80~90% oil from seeds. This means that the total remaining oil content in the full-pressed cake is around 10~20%.

3.Refining section

Main Equipment for Refining Soybean Oil

| No. | Device name | Number | Description |

| 1 | Refining pot | 2 | Alkali and water washing for oil, stainless steel |

| 2 | Decolorizing pot | 1 | Used to dry oil and remove oil pigment |

| 3 | Filter | 1 | Separation of oil and clay |

| 4 | Deodorization pot(alternative) | 1 | Removal of acid, odor substances and volatiles from oil, stainless steel |

| 5 | High-efficiency vacuum pump | 1 | Vacuum generating device |

| 6 | Thermal oil furnace | 1 | Provide heat energy for production, temperature up to 300℃ |

| 7 | Vapor heat exchanger | 1 | Production of steam |

| 8 | Gas-liquid separator | 1 | Separation of deodorized saturated steam’s excess moisture |

Soybean oil Refining Process Flow

Crude oil→Heating→Mixing→Alkaline reining→Precipitate separation→Heating→Washing→Separating→Vacuum drying and decolorizing→Deodorization→Cooling→Filtrating→Finished oil